testing rock hardness with a knife|how to test hardness of quartz : OEM The relative hardness of minerals is a property that tested using a scratch method. The harder mineral will scratch the softer one. The Mohs scaleof mineral hardness consists of 10 minerals used for the scratch test. Also, tools like glass or a knife with known hardness can be used for this test. See more webSwagNorth has the promotional items you need to get your business noticed. With our product expertise, global partners and dedication to our customers, SwagNorth is your .

{plog:ftitle_list}

web11 de jan. de 2023 · Com A Mandíbula de Caim, o autor estabeleceu novos parâmetros para o gênero de suspense investigativo e abriu portas para o lançamento de obras instigantes e capazes de estimular os leitores a .

The relative hardness of minerals is a property that tested using a scratch method. The harder mineral will scratch the softer one. The Mohs scaleof mineral hardness consists of 10 minerals used for the scratch test. Also, tools like glass or a knife with known hardness can be used for this test. See moreA scratch test can be easily done at home with a list of simple tools or with several known minerals. It is a quick method for the determination of . See more

A scratch test is used to determine the relative hardness of minerals and to identify a stone according to the Mohs scale of relative hardness. A scratch test is one of the most . See more

One key to identifying mineral species is to test its hardness. Mineral hardness tests can be performed at home or on a rockhounding field trip. There are necessary tools for express hardness testing: A fingernail, a . The Mohs Hardness Scale is a widely recognized and simple scale for measuring the scratch resistance of various minerals. Created by Friedrich Mohs, a German geologist, in 1812, it remains a standard in geology, .The steel blade of the average knife usually has a hardness of about 5.5. If a penny does not scratch your unknown specimen but the knife blade does, then you can correctly conclude that it is harder than calcite (H=3) but softer than .

They are supplied with a hardness of 2 (a plastic point), 3 (a copper point), and 4 through 9 (carefully selected alloys). They are great for testing small specimens or for testing small grains embedded in a rock. These hardness picks are .

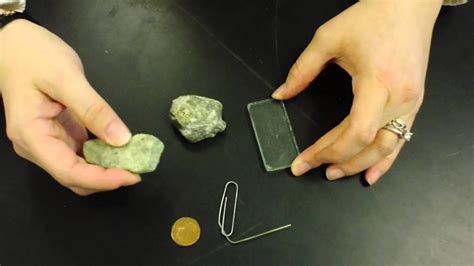

Learn how to master the scratch test with our step-by-step guide. Gather your tools, attempt the scratch, observe the results, repeat with other objects, and compare with the Mohs Hardness Scale.

A simplified and crude test for hardness is to test whether or not a sharp corner or edge of a sample scratches (or indents) a glass plate. A numerical reference scale for hardness was . The Mohs hardness scale is a qualitative test that measures the hardness of a mineral by its ability to visibly scratch softer minerals. The scale isn’t perfect, but it’s a great tool for quick identification of rocks in the field. .

You use the Mohs hardness scale by testing an unknown mineral against one of the standard minerals. Whichever one scratches the other is harder, and if both scratch each other they are the same hardness. .Also, Rockwell hardness test only reveals the surface hardness of a material and not its internal hardness. Apart from the Rockwell hardness number, other qualities of a knife blade that should be considered to determine the quality of . Steps for Performing the Mohs Hardness Test . Find a clean surface on the specimen to be tested. Try to scratch this surface with the point of an object of known hardness, by pressing it firmly into and across your test .Additional Rocks. Shale: 2-3 (very soft, easily scratched) Limestone: 3 (scratched by copper penny) Marble: 3-4 (softer than granite, often used in sculpture) Slate: 3-5.5 (depending on composition) Granite: 6-7 (hard, durable, used in countertops) Basalt: 5-6.5 (volcanic rock) Hardness Variations in a Single Mineral. It is essential to note that hardness can vary within a .

stone hardness test

Hardness testing can be applied to various types of materials, some of which are listed below: Metals and alloys. Ceramics. Elastomers. Polymers and plastics. Films. Rocks and minerals. Importance of Hardness Testing. Hardness testing is important for a number of different reasons. The hardness of a material can be a critical parameter in its .

how to test mineral hardness

The Rockwell hardness of knife steel determines how strong or hard the steel is. The rating shows how resistant the blade is to permanent deformation or penetration by another material. . Here is how the test calculates the hardness of steel: . This stainless steel knife set features rock solid design crafted from durable materials; With a .How to conduct a hardness test on an unknown rock or mineral using Mohs Scale of hardness. Customer Service: 1.406.827.8273. . The steel blade of the average knife usually has a hardness of about 5.5. If a penny does not scratch your unknown specimen but the knife blade does, then you can correctly conclude that it is harder than calcite (H=3 . Try to scratch the mineral with a copper penny. Work with the same mineral sample and get out a copper penny. The penny has a hardness level of 3 compared to the 2.5 hardness of your fingernail. This number helps consumers understand the knife's potential for edge retention, as well as its ability to withstand impact and wear. Understanding the Rockwell Hardness Values: Soft Blades (Low Rockwell Hardness): Kitchen knives with lower Rockwell Hardness values, typically in the range of 52-56 HRC (Rockwell C Scale), are considered soft.

In this step-by-step guide, we'll walk you through the process of conducting a scratch test to determine the hardness of a rock. Step 1: Gather Your Tools . To begin, you'll need an object of known hardness. This could be a fingernail, a copper penny, a steel knife, or a piece of glass. These objects will serve as your testing tools. Step 2 .

Mohs hardness kit, containing one specimen of each mineral on the ten-point hardness scale. The Mohs scale (/ m oʊ z / MOHZ) of mineral hardness is a qualitative ordinal scale, from 1 to 10, characterizing scratch resistance of minerals through the ability of harder material to scratch softer material.. The scale was introduced in 1812 by the German geologist and mineralogist . Perform the Mohs Hardness Test. The Mohs hardness test is easily performed. You need examples of items with known hardness values. Handy materials include: your fingernails (2.5) a copper coin or piece of chalk (3.5) a pocket knife or piece of glass (4.5-5.5) a quartz point or unglaze porcelain (7.0) a hardened drill bit (8.5)

Hardness is the last mineral test we’ll perform on the rocks. Also called a scratch test, Mohs Hardness Test looks at whether or not a mineral can be scratched by another mineral. Mohs Hardness Scale has ten minerals of known hardness. You scratch your rock with each of these minerals to determine where your rock falls on the scale.

The rockwell hardness test measures the knife blade’s ability to resist deformation or indentation under pressure. Different materials used in kitchen knife production can result in varying rockwell hardness ratings. In this section, we will explore the rockwell hardness ratings of various kitchen knife types to help you determine which . On the Mohs scale, fingernail has hardness 2.5; copper penny, about 3.5; a knife blade, 5.5; window glass, 6.5; steel file, 6.5. Using these ordinary materials of known hardness can be a simple way to approximate the position of a mineral on the scale. . If it is scratched then the rock you're testing is hardness 1. If not then try to scratch .A Rockwell hardness tester. The Rockwell scale is a hardness scale based on indentation hardness of a material. The Rockwell test measures the depth of penetration of an indenter under a large load (major load) compared to the .

Rockwell testing can leave a mark on the steel, which is why many makers measure it on a part of the steel that’s concealed by the handle. . 62 RC is very hard so that’s good, it’s important to take the steel material, heat .Rock Hardness using Mohs . Activity Summary . In this activity, using household objects and the Mohs Hardness Scale, you will explore the . Collect a variety of rocks to test. If your rocks have soil on them be . Slowly work up the Mohs scale (copper coin, glass/knife, steel nail, masonry drill bit) until you can find a scratch. A scratch .

2004 lincoln navigator compression test

In this advanced knife making tutorial, I discuss why knife makers should test the hardness of their blades and demonstrate how I use the Ames Model 1 to tes.

2004 lincoln navigator compression test youtube

Mohs Hardness Test: A qualitative scale that ranks minerals from 1 to 10 based on their scratch resistance. For example, talc is rated 1, while diamond is rated 10. . mineral is between 3 and 4. Alternatively, one can use a fingernail (hardness 2-2.5), a coin (hardness 3.5), or a small knife (hardness 5.5) to scratch the mineral in order to .York Saw & Knife uses Rockwell hardness testing on all our customers’ blades as part of our quality-control process. If you require a soft steel alloy in the RC 40 range, you can be sure our techs have tested it to verify that hardness rating before we ship it from the factory. Likewise, if you’ve ordered tough blades with tensile hardness .

The hardness test can be performed with everyday materials and requires no special equipment. Hardness is the resistance of a substance to scratching by another material. A scratch is . Pocket knife blade* 5 Glass plate (window glass) 5.5 Steel file (chain saw file) 6.5 Quartz 7 American Education Hardness Collection with Test Kit Rating Conclusion. To wrap it up, the Mineral testing kit (Amazon link) is the industry and Rockhound premium standard because it is exact and easy to carry with you and use in the field.. For rockhounds who are more interested in the geology of useful and industrial minerals, especially metals, the TTC file .

Fluorite 4 Can be scratched easily with a knife, cannot scratch glass . When we test we carefully hold the rock being tested so that if the pick slips . Some people use a few common objects for Mohs hardness testing in the field. A fingernail, a copper coin, a nail, a piece of glass, a knife blade, a steel file, a streak plate, and a piece .Deluxe Hardness Test Kit and Pick Set from Mineralab, featuring top quality picks made of metals and alloys of hardness values equal to 2 through 9 on the Mohs hardness scale. . Pencil sized X-Acto retractable blade knife with pocket clip - Great for cutting lightweight material and scratching rocks for hardness testing. (Item #1590) .59 .16pc Steak Knife and Bistecca Plate Set + 8" Chef's Knife + 3.5" Paring Knife Bundle 9.99 4 22% Savings (157) Aprons Aprons. Eco Modern Apron Benny's Eco Modern Apron Shop all Aprons > View product detail Eco Modern Apron (Ecru) (22) View product detail Eco Modern Apron (Slate) (22) .The common objects are referred to as 'tools' by geologists. A field geologist normally carries a pocket knife for a quick hardness test of rocks and minerals. Note the hardness values of these 'tools'. fingernail. copper coin. steel blade of a pocket knife. steel nail. masonry drill bit

Some of the properties of minerals include hardness, color, shine, and breaking. There are different tests that can be used to determine minerals’ properties. One of those tests is a scratch test. This test is used to determine the hardness of a mineral and can be performed by simply using a nail to scratch the surface of a mineral. Problem:

how to test hardness of steel

Welcome to NVIDIA GeForce NOW's home for real-time and .

testing rock hardness with a knife|how to test hardness of quartz